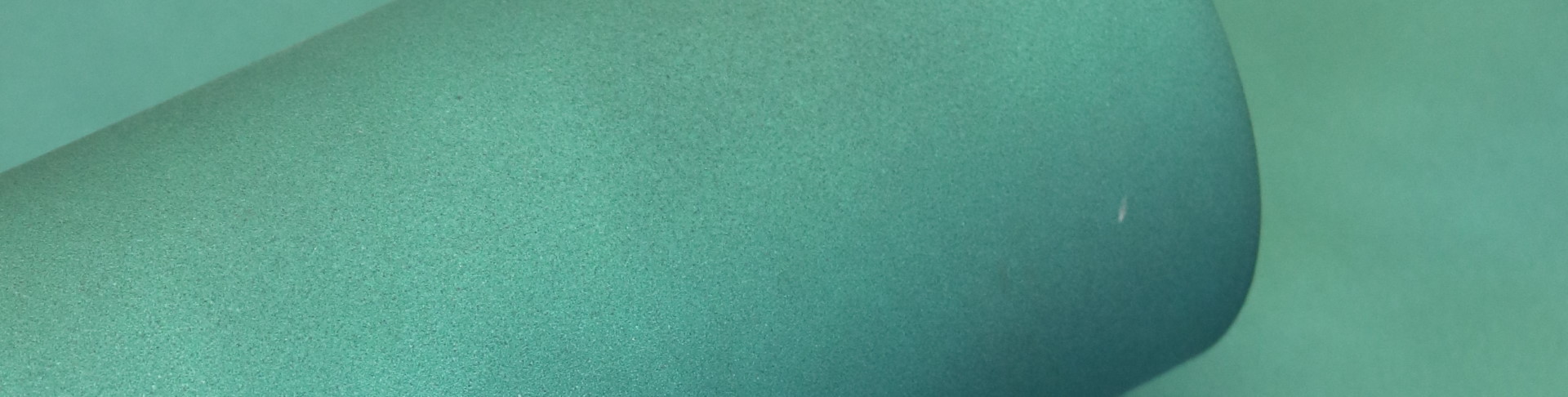

Elegant creased and wrinkled effect finish

Products formulated thanks to the yearly experience of Cromas in special paints, are EU-approved and provide an always increasing performance and successful results. We can proudly say that the wrinkle paint has been chosen by the most popular Italian brands of sports cars to finish valve covers and parts of the car engine, in the automotive sector.

Elegant creased texture effect of the wrinkle paint

Black wrinkle paint

Red wrinkle paint applied to valve cover of a sports car

Red wrinkle paintThis quality product has successfully passed the saline mist test of 500 hours in compliance with manufacturers methods. The available colors of the wrinkled finish are lively red, black and aluminium. Other colors will be provided upon request but some technical limits – imposed by the characteristics of the product – must be taken into account.

The application of the wrinkle paint to metallic supports gives two main advantages: increases resistance and covers imperfections.

By the vitue of the elegant and exclusive texture achieved by the wrinkled effect (also called vermiculated or vermiculation effect), the paint has always been used to give a pleasant look and tactile sensation to surfaces. Plus, thanks to the state-of-the-art raw materials that make up the paint, the final product achieves greater resistance to both corrosion and gasoline.

Application and curing of wrinkle paint

This finish is suitable for professional and industrial users only. The recommended application is by airbrush mixed air or pump.

It is advised to use medium-sized to large spray nozzles with pressure range 1,8-2,5 mm to 3-4 Atm so as to prevent dilution of the paint. The size of wrinkles is determined by the application thickness of the paint. For such applications, a higher quantity of paint is needed – compared to common applications on iron.

The most used application thickness is 300 microns wet which allows to reach crinkles of medium size. Very thin crinkles are achieved by 200 microns wet. Greater crinkles used in automotive products need a thickness of 500 microns wet. It must be said that the application of the wrinkle paint at such thickness values over complex items can be only managed by expert hands who hold deep knowledge of the product and experience in spray painting.

After the application of the paint, it should be left to dry for about 10-15 minutes. After that, it is necessary to cure products in the oven at a minimum temperature of 80° for 90-120 minutes. At this step, the support will achieve a wrinkled look.

It is advised to bake at 80°C since curing at lower termperatures would lead to non uniform results and because the effect could not be perfectly reproduced in series production. The end result would be suitable for occasional or private customers only.

It is important that items are placed in the oven only when this one has reached the recommended temperature. After baking, the products reach the desired visual aspect. Though, if the baked items must be assembled, we advice a post-baking at 60-80°C to determine faster curing of the paint.

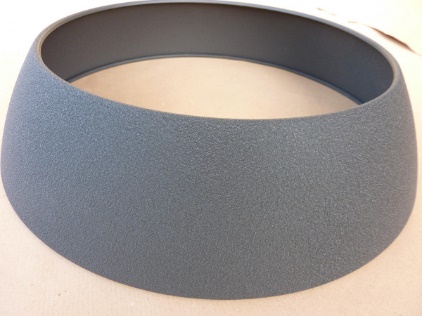

Grey wrinkle paint: elegant creased look

Grey wrinkle paint

Particular of aluminium wrinkle paint

Aluminium wrinkle paintFurther important technical information about wrinkle paint

Curing in oven at 80°C is a fundamental requirement to achieve reproducible results in industrial production. Curing at lower temperatures would reach intermediate and non satisfactory results. It is advised to check both the temperatures of the oven and, most importantly, of the item before proceeding with baking.

Not all colors can be obtained. In order to achieve total white color you should apply two hands of paint.

When dealing with restoration or makeover the application must be done on a totally clean surface, without any residue of previous painting. Polished metals need carefull sanding or blasting before the application of the paint. In general, any application must be carried out on a perfectly clean surface and without residue of paint.

The wrinkled effect can be successfully achieved if baking is made at a minimum temperature of 80°C so it can be applied only to iron, aluminium and glass filled nylon because they hold a high Tg and do not turn soft in the oven.

When using ovens with higher temperatures (i.e. 130-150°C), it is advised to leave the product at a temperature of 80°C for a long time, before proceeding with the baking. That would allow a better wrinkling process.

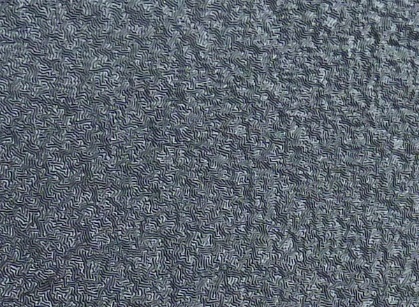

Focus on black wrinkle paint. It can be noticed the crinkle textured look

Black wrinkle paint

Black wrinkle paint applied on metal

Black wrinkle paintThe product is currently available as solvent-based only.

The wrinkle finish can be applied with or without the use of a primer to:

- metal (iron, aluminium, brass, etc.)

- plastic (6,6 glass filled Nylon 6.6, 12 glass filled nylon, other plastic materials must be verified through testing)