Create real polished metallic decorative effect, applied with spatula.

This is an epoxy resin with a high concentration of metallic microspheres to produce and a unique and beautiful metal shine. Developed for manufacturers and professional users.

Pure Metal is an exclusive product designed to create a real polished metal finish on many surfaces including furniture, decorative objects, wall and door decorations and flooring.

The surfaces decorated with resins from the Pure Metal Collection have a very metallic and brilliant shine with a textured and three-dimensional feel.

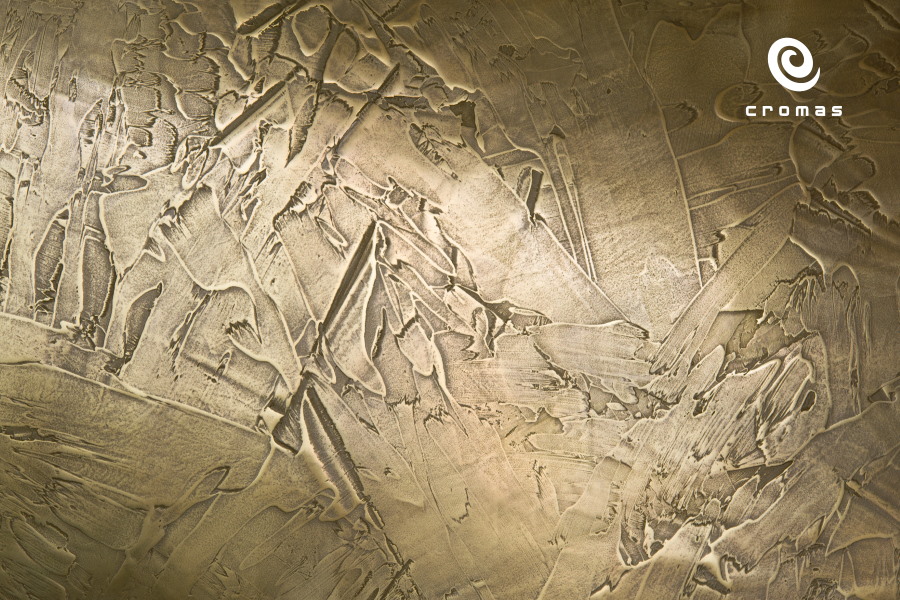

Metallic epoxy resin, Burnished Brass

Metallic epoxy resin, colour PM.08, BURNISHED BRASS, Pure Metal CollectionThe metal particles in this mixture allow for the creation of unique shades of metallic colour that reflect the light and also show the darker burnished areas. Because the resin is applied with a spatula, then sanded and polished, it is simple to create an amazing textured effect.

A surface that has been polished reflects brightly in the light just like real metal. This product is based on a solvent-free and water-free metallic epoxy resin with 100% solids materials. The product looks like a thick plaster and comes in various colours depending on the metallic colors in the mix.

With Cromas Paints scientific experience in producing special effect paints and resins, we have developed this metallic resin for professional applications. We created a unique range of 10 metallic shades with beautiful natural and burnished colours. The colours allow the user to create a unique polished surface that is reflective and with the option to add a three-dimensional texture to the surface.

Our Pure Metal resin is different from other similar products because the quality of the reflective and darker burnished surfaces are a result of the polished real metal in the mixture. We do not add extra colours to change the look of the surface.

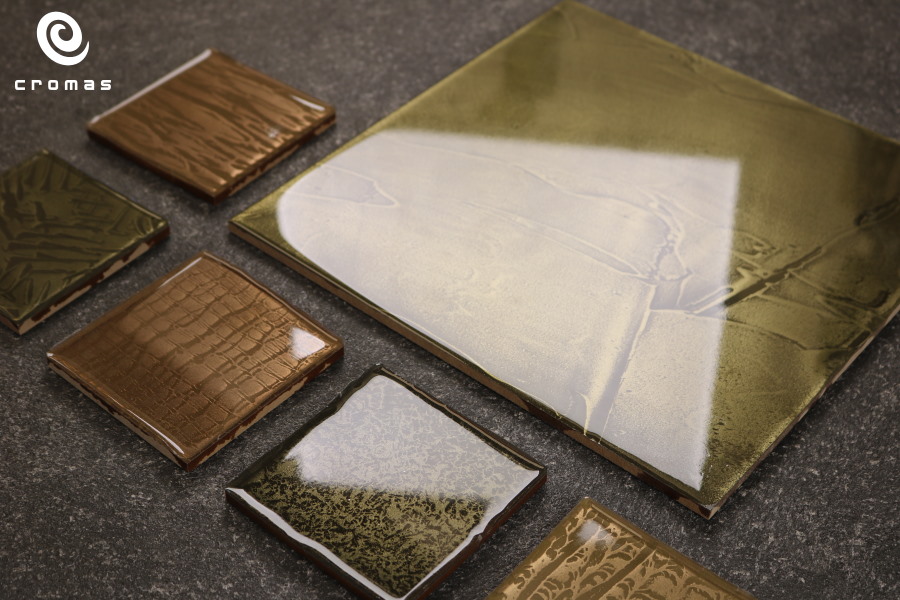

The colours available in the collection are:

Metallic epoxy resin, polished Zinc

Metallic epoxy resin, polished Zinc, Pure Metal Collection, colour PM.01 ZINC

Metallic epoxy resin, polished Brass

Metallic epoxy resin, polished Brass, Pure Metal Collection, colour PM.02 BRASS

Metallic epoxy resin, polished Bronze

Metallic epoxy resin, polished Bronze, Pure metal Collection, colour PM.03 BRONZE 5050

Metallic epoxy resin, polished Bronze

Metallic epoxy resin, polished Bronze, Pure Metal Collection, colour PM.04 BRONZE 7030

Metallic epoxy resin, polished Copper

Metallic epoxy resin, polished Copper, Pure Metal Collection, Colour PM.05 COPPER

Metallic epoxy resin, polished Burnished Zinc

Metallic epoxy resin, polished Zinc, Pure Metal Collection, colour PM.06 BURNISHED ZINC

Metallic epoxy resin, polished Burnished Brass

Metallic epoxy resin, polished Burnished Brass, Pure Metal Collection, colour PM.07 BURNISHED BRASS

Metallic epoxy resin, polished and Dark Burnished Brass

Metallic epoxy resin, polished Dark Burnished Brass, Pure Metal Collection, colour PM.08 DARK BURNISHED BRASS

Metallic epoxy resin, polished Burnished Bronze

Metallic epoxy resin, polished Burnished Bronze, Pure Metal Collection, colour PM.09 BURNISHED BRONZE

Metallic epoxy resin, polished Burnished Copper

Metallic epoxy resin, polished Burnished Copper, Pure Metal Collection, Colour PM.10 BURNISHED COPPEROptional Textured Effects with the Pure Metal Resin

Due to the high viscosity of this resin and the concentration of metal microspheres, users can create many dfferent textures on the surface that will not sag or change shape. After the mixture has been applied with a metal trowel or spatula, the surface can be finished based on the desired final effect.

The textured finishes in the Pure Metal Collection can be consistantly reproduced on items and surfaces used in series production. These textures are achieved by using a decorative roller.

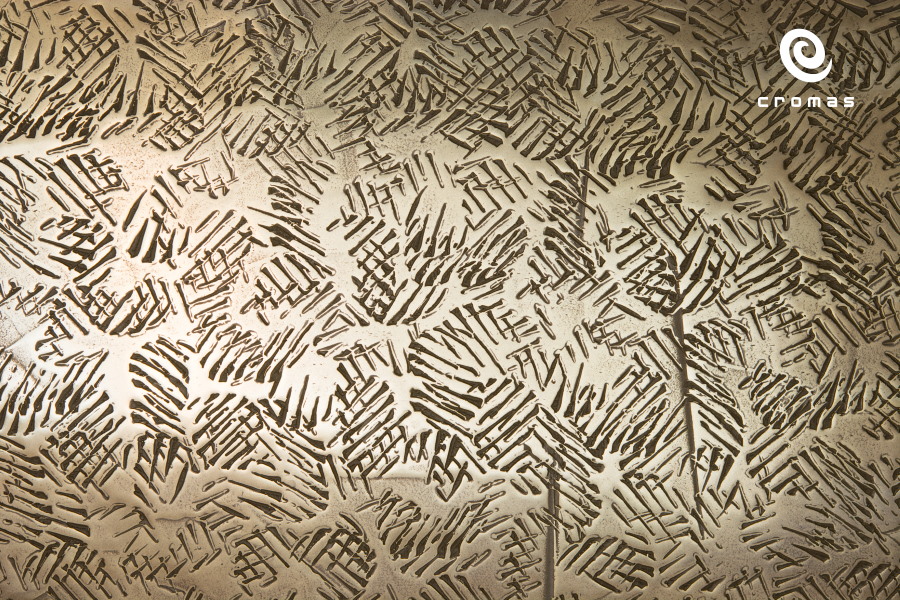

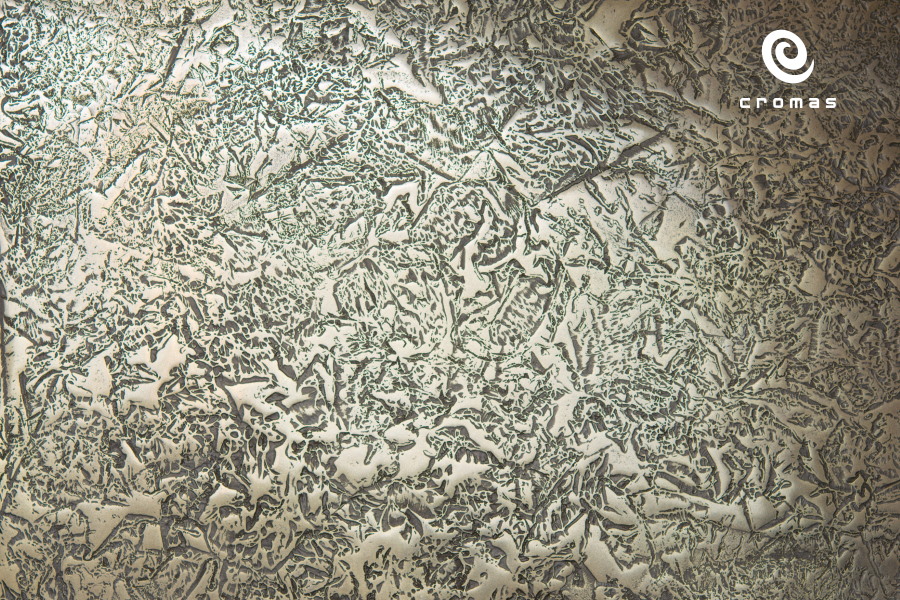

Metallic epoxy resin, Desert Path texture

Metallic epoxy resin, example of Desert Path texture applied to PM.04 BRONZE 7030

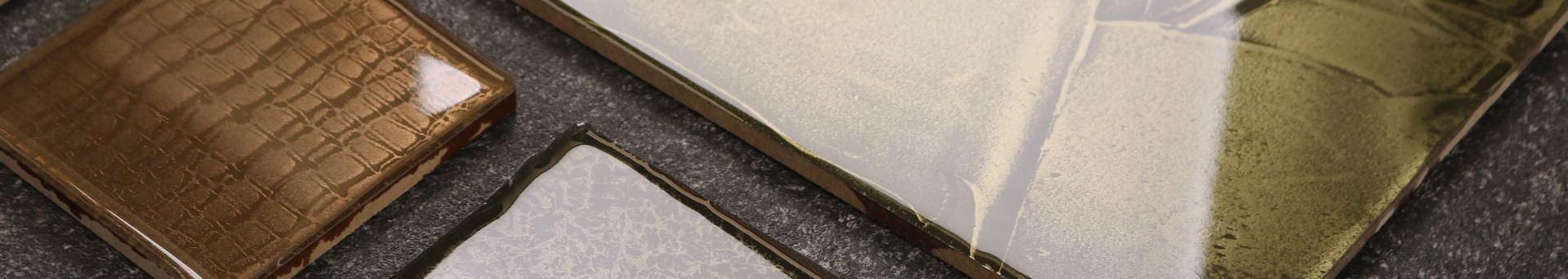

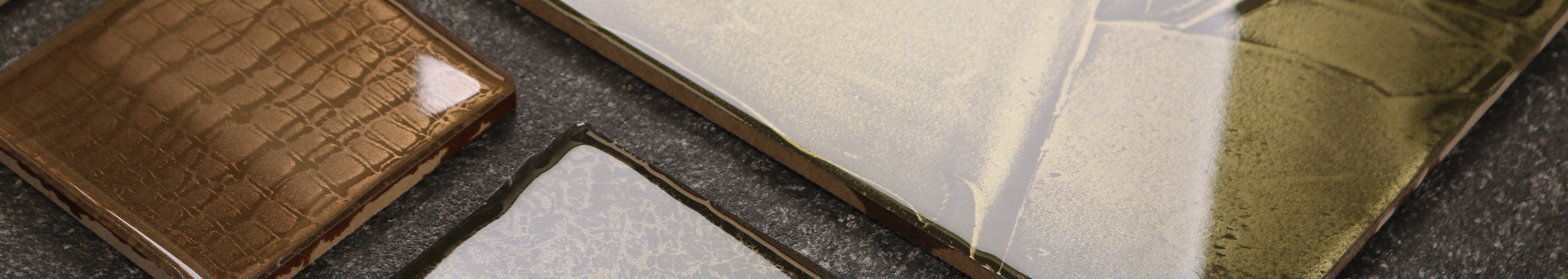

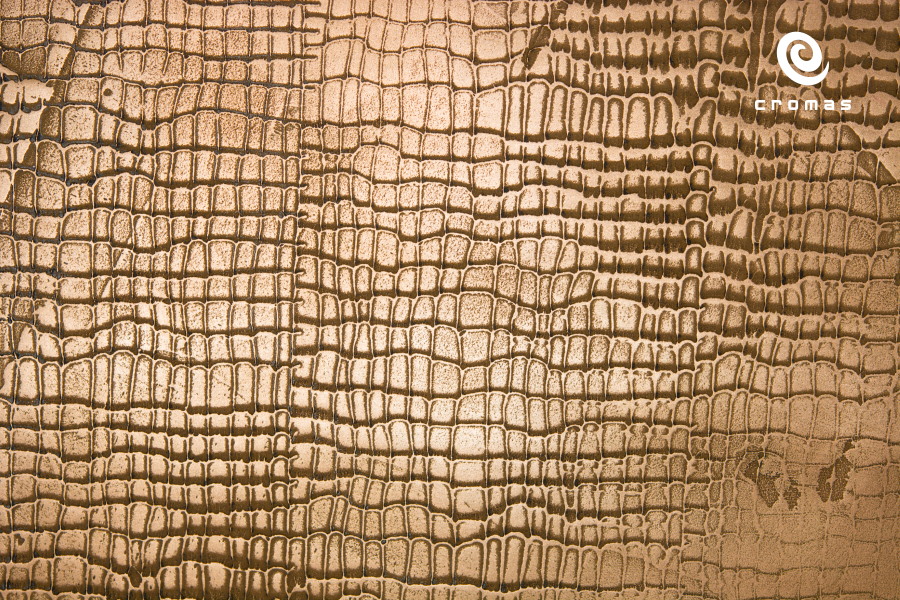

Metallic epoxy resin, Hunter Dream texture, reptile effect

Metallic epoxy resin, example of Hunters Dream texture, reptile effect applied to PM.04 BRONZE 7030

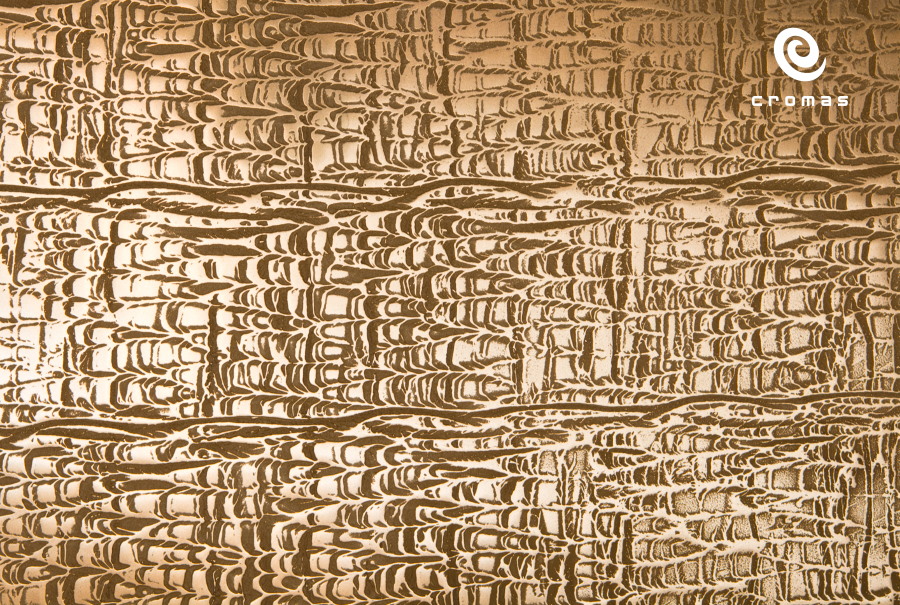

Metallic epoxy resin, Ancient Time texture

Metallic epoxy resin, example of Ancient Time decoration applied to PM.04 BRONZE 7030

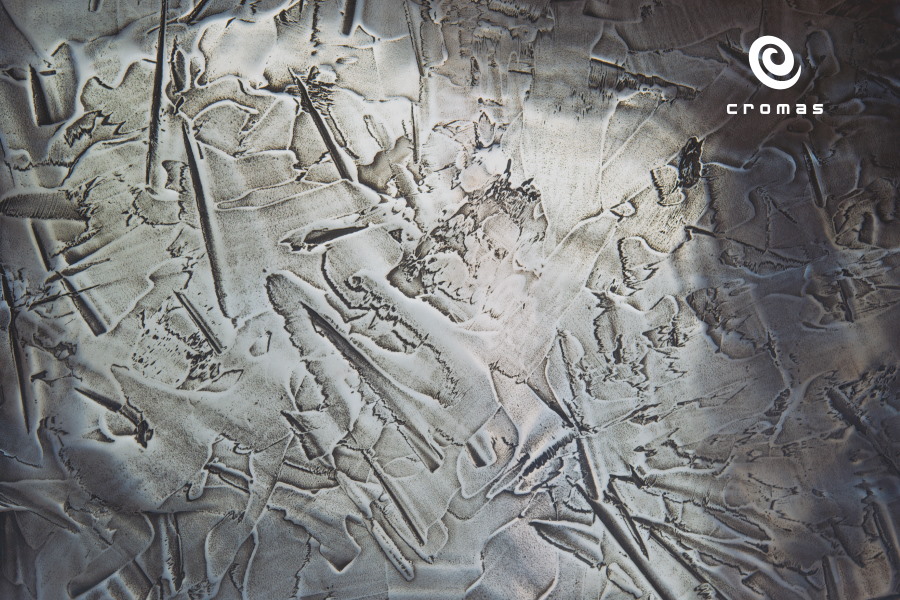

Metallic epoxy resin, Industrial Era texture

Metallic epoxy resin, example of Industrial Era decoration applied to PM.07 BURNISHED BRASS

Metallic epoxy resin, Silk Road decoration

Metallic epoxy resin, example of Silk Road decoration applied to PM.08 DARK BURNISHED BRASSIn summary, the colours of the Pure Metal Collection are:

- PM01 ZINC

- PM02 BRASS

- PM03 BRONZE 5050

- PM04 BRONZE 7030

- PM05 COPPER

- PM06 BURNISHED ZINC

- PM07 BURNISHED BRASS

- PM08 DARK BURNISHED BRASS

- PM09 BURNISHED BRONZE

- PM10 BURNISHED COPPER

Our range of textured finishes:

- HUNTERS DREAM (use roller in straight line, reptile effect)

- SILK ROAD (crumpled paper)

- INDUSTRIAL ERA (random rolling on surface, grid effect)

- DESERT PATH (use roller in straight line)

- ANCIENT TIME (use roller in cross direction)

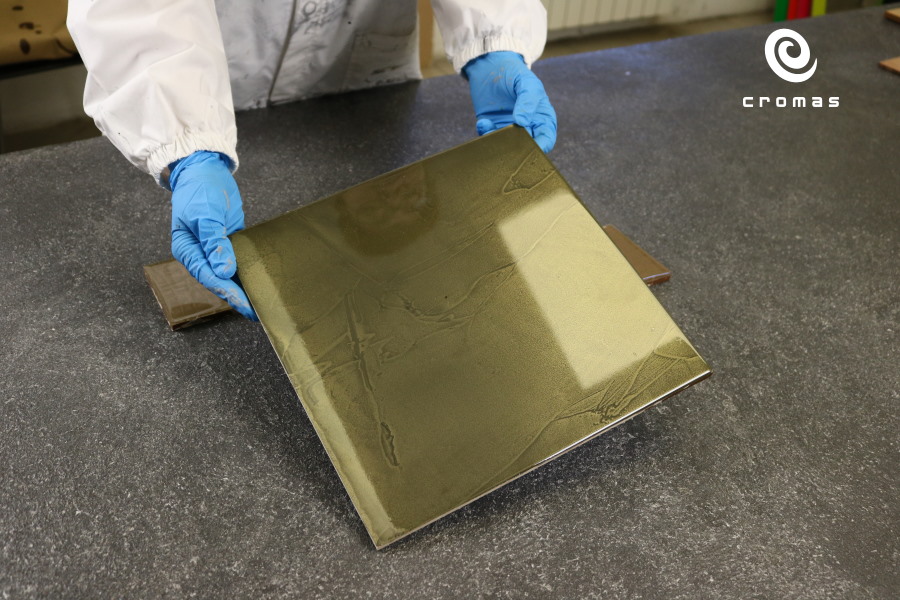

General and Important Information about Application Technique

Pure Metal is a two-component epoxy resin that is mixed with a hardener. When the based is mixed, it looks like a thick paste that is usually dark in colour. It is thick., but smooth, so that it can be applied with a spatula or trowel. It can also be applied on vertical surfaces with a trowel. The curing time is at least 24 to 48 hours.

After at least 48 hours from the application, it is possible to sand and polish the hard resin. Using an orbital sander, sand with a series of sandpaper grit sizes from 180-240 / 320 / 500 / 1200. After the sanding is completed, use a polishing machine and a polishing compound to polish the surface to a brilliant shine as seen in the pictures.

The end result is a very durable and hard surface with high scratch resistance. The characteristics and texture of the finished Pure Metal surface will depend on the application style with the trowel and if a three-dimensional texture was added.

Because the effect is a polished metal surface, it can oxidize or change with time. But it can be polished again to bring back the shine. We do not suggest to apply waxes or a topcoat unless necessary. An option to add a durable topcoat is to use our Transparent Resin. Apply the Low Thickness resin as a glaze to seal the surface and add a high level of resistance plus a beautiful glossy shine.

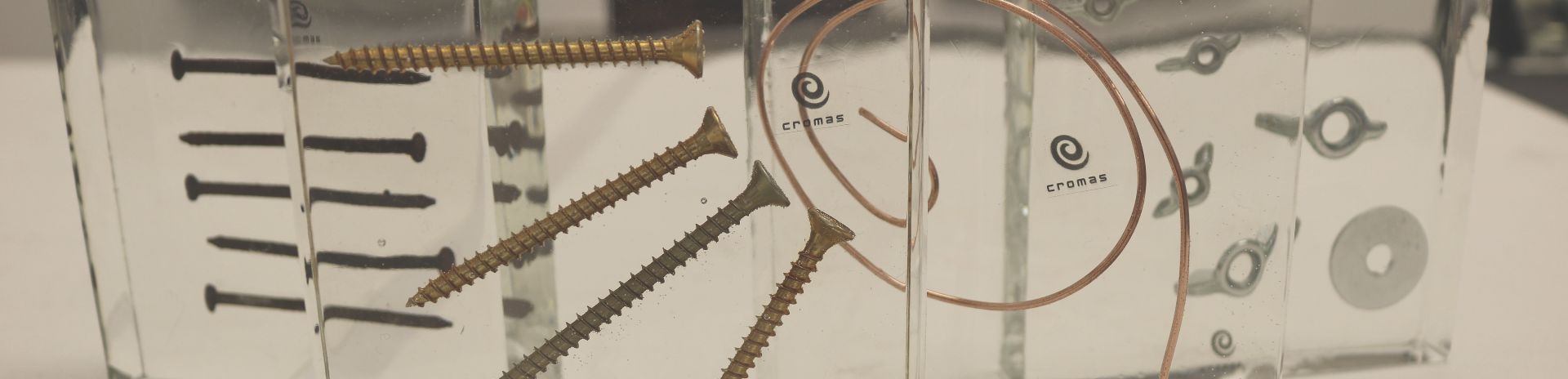

Metallic epoxy resin, application of crystal clear resin topcoat

Metallic epoxy resin. Application of self-leveling transparent glaze topcoat

Metallic epoxy resin, application of Low Thickness resin topcoat

Metallic epoxy resin, application of self-leveling glazing resinWe recommend to apply a suitable primer over the surface before the application of the Pure Metal base. For applications with a three-dimensional texture, we suggest to also apply a coloured primer layer that is dark brown or a colour close to the resin mix colour. The reason is that when sanding and polishing the surface – and if the material is thin in some areas – you can sand through the resin. If this happens you will see the paint colour and not a white primer.

Application and Storage Requirements

The viscosity of the resin is changed by temperature, so the products must be stored in warmed environments during winter. Before application, we advise to warm up the product to a temperature of about 20° C.

In the winter, the application of the resins must be carried out in a warm work area. The recommended temperature during hardening time is over 20° C. At lower temperatures, the curing time increases before the surface becomes hard and ready for polishing.

The resin must not be applied in a humid working environment and on humid surfaces. This is necessary to assure the resin has good resistance to Carbonation.

It is important that the working environment and items or surfaces are moisture free.

The Importance of Pre-Production Testing

The application process of casting, self-leveling, or encasing objects in epoxy resins is not difficult, but our experience tells us that it is necessary to proceed with testing, to develop your standardized application process especially if there is no previous experience with resins. Cromas Paints goal is to give you the most useful information so your projects are successful. The provided information comes from our direct experience. Because there are many factors to consider, we always advise to proceed with product testing in a controlled working environment and using the same materials.

Related products

-

![front image - Phosphorescent Epoxy Resin]()

Phosphorescent Epoxy Resin

![back image - Phosphorescent Epoxy Resin]()

Phosphorescent Epoxy Resin

-

![front image - Epoxy resin for three-dimensional decorations]()

Epoxy resin for three-dimensional decorations

![back image - Epoxy resin for three-dimensional decorations]()

Epoxy resin for three-dimensional decorations

-

![front image - Transparent coloured epoxy resins]()

Transparent coloured epoxy resins

![back image - Transparent coloured epoxy resins]()

Transparent coloured epoxy resins

-

![front image - Low thickness casting epoxy resins]()

Low thickness casting epoxy resins

![back image - Low thickness casting epoxy resins]()

Low thickness casting epoxy resins

-

![front image - Medium thickness casting epoxy resins (up to 3 cm) and small encapsulations]()

Medium thickness casting epoxy resins (up to 3 cm) and small encapsulations

![back image - Medium thickness casting epoxy resins (up to 3 cm) and small encapsulations]()

Medium thickness casting epoxy resins (up to 3 cm) and small encapsulations