Two material finishes with verdigris effect: false copper oxidation and real copper oxidation

To satisfy the numerous requests in the market of the material finishes, Cromas developed two different visual and tactile effective solutions:

- Verdigris material effect, it’s a false chemical oxidation extremely material and realistic, that allows to obtain a color effect where elevated resistance, even in the outdoors, and simplicity in application merge.

- Real verdigris effect, with stabilized copper particles that, after painting, get oxidized directly on the support creating stains of real verdigris

VERDIGRIS MATERIAL EFFECT: AX.03 CLASSIC VERDIGRIS

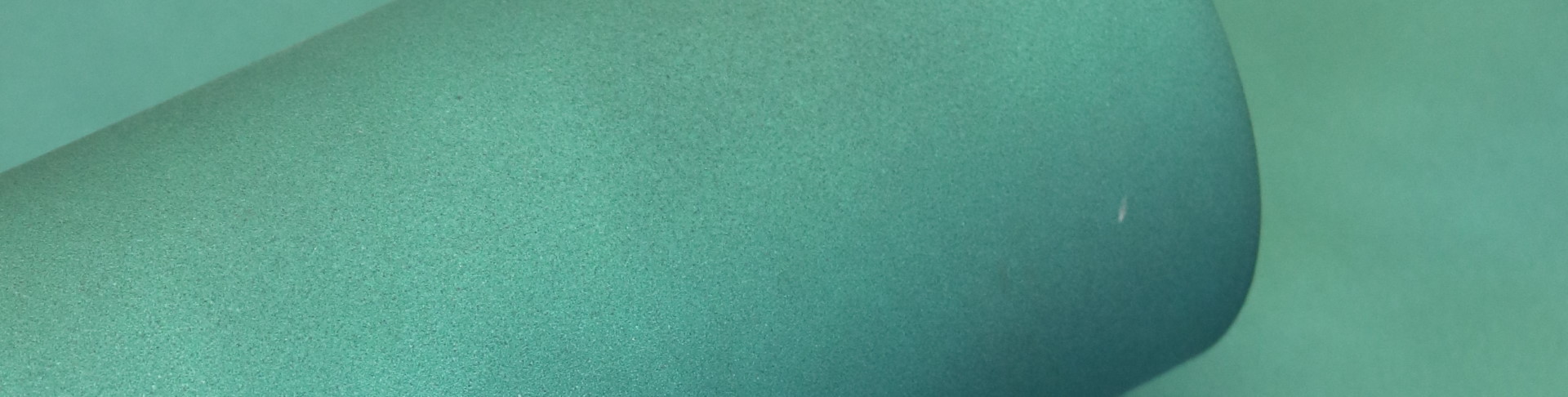

Verdigris effect paint, material finish with false oxidation. Detail.

Verdigris effect paint, material finish with false oxidation. Detail

Verdigris effect paint, material finish with false oxidation. Detail

Verdigris effect paint, material finish with false oxidation. Detail

Verdigris effect paint, material finish with false oxidation. Detail

Verdigris effect paint, material finish with false oxidation. DetailThis finish has been developed to simplify and make the surface more resistant, while keeping the real aesthetic effect of the oxidized copper.

Main characteristics of the product:

- Simplicity of application, both on vertical and horizontal surfaces

- Elevated resistance: can be used for indoor and outdoor spaces (resistant to UV rays)

- Very realistic visual and tactile appearance: the color has been created after reading many samples of verdigris with a spectrophotometer and it has been formulated with pigmented microspheres to obtain a material surface

- Spray only application and solvent based, a water based version is under study

Cycle of application, quick and simple:

- White primer

- Verdigris effect application AX.03 CLASSIC VERDIGRIS

- Matte transparent finish

The application cycle is shown in the following tutorial video:

REAL EFFECT VERDIGRIS: XV.04 VERDERAME – VERDIGRIS

Exclusive finish for the creation of a real verdigris effect that would surely have a visual and tactile impact: stabilized copper microspheres mixed in the paint and oxidized directly on the support. The final effect is impressive, verdigris stains separated by non oxidized metal. Every surface becomes unique and unrepeatable, like the metals affected by the elements for years.

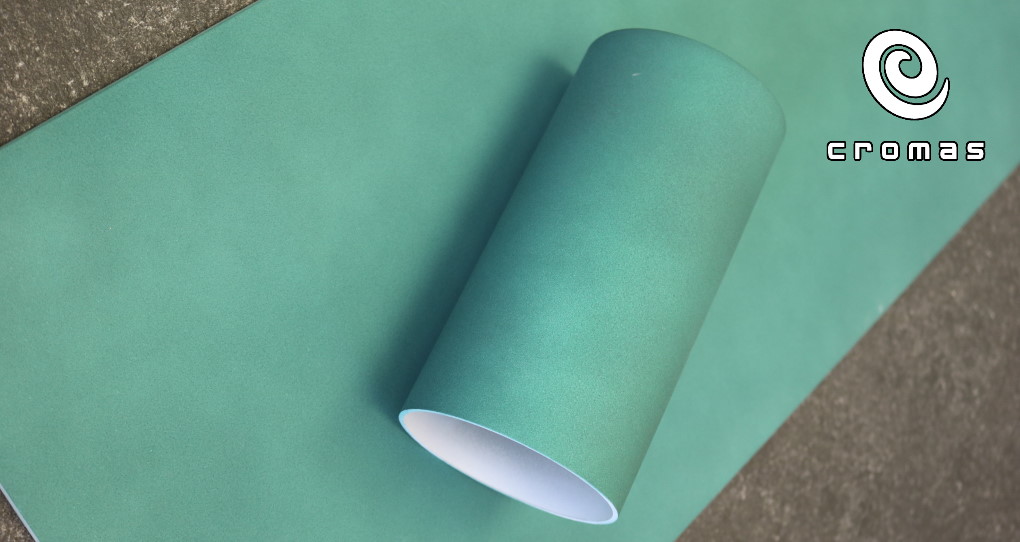

Verdigris effect paint, materic finish with real oxidation. A particular

Verdigris effect paint

Verdigris effect paint, materic finish with real oxidation.

Verdigris effect paint

Verdigris effect paint, materic finish with real oxidation. Application on metal.

Verdigris effect paint

Verdigris effect paint, materic finish with real oxidation. Application on metal.

Verdigris effect paint

Verdigris effect paint, materic finish with real oxidation. Application on MDF wood.

Verdigris effect paintMain characteristics of the product:

- Realistic appearance: real oxidized copper is present on the surface

- Possible application on vertical and horizontal surfaces. On vertical surfaces the oxidation is less strong but gives a washed effect.

- Only suitable for indoor environments

- Spray only application and solvent based

Cycle of application:

- White primer (anti-corrosion on iron)

- Verdigris effect application XV.04

- Light sanding, only to activate the metal on the surface

- Oxidation with REATTIVO N100

- Light rinsing with water

- Corrosion blocker

- Final matte transparent finish

The application cycle is shown in the following tutorial video. In this video, beside the verdigris application, we show the application of the other oxidized metals that have the same painting cycle.

We suggest to apply with airbrush or joint air pump. Once the metallic base is dry, a light sanding is performed and then oxidation with a light oxidative substance in a few hours will do the job of years of bad weather. The work ends with a transparent blocker and afterwards with a matt finish that allow to have a resistant surface. The suggested destination of the painted surface is still for interior environments.

The oxidation can be more or less strong, it depends on the number of passages of oxidant, on the environmental conditions and on the needs. The horizontal applications are the ones that give more oxidized supports, the vertical surfaces are usually lighter but bring a washed out appearance, requested by many clients.

Given the variability of the oxidation, we recommend to always perform a test before starting the production.

The effect can be applied, with the use of a primer, on:

- Wood

- Metal (ireon, aluminum, brass, etc…)

- Plastics (ABS, ABS-PC, etc…)